Introduction:

Embark on a journey into the heart of GPU repairs with my debut video at Graphic Card Repairs. As a seasoned system administrator, I wear multiple hats, supporting two companies and dedicating three days each week to graphic card repairs. Join me as I demystify the seemingly complex process of reballing a GDDR6 memory chip extracted from a 6800 XT, using a basic yet effective setup.

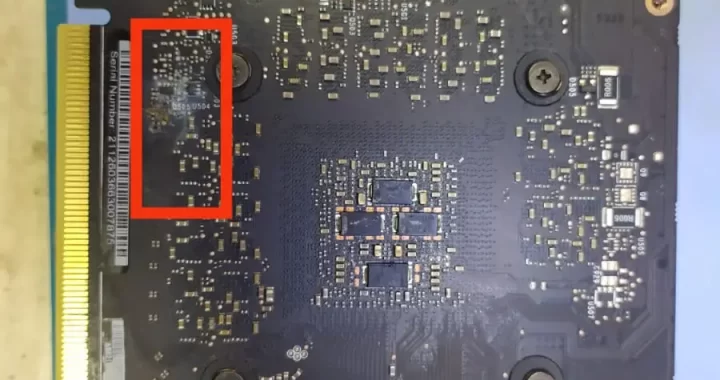

Setting the Stage:

Let's start by exploring my workspace, a simple setup with an overhead camera providing a crystal-clear view of my work area. My role involves supporting two companies, and three days a week are dedicated to the intricate world of graphic card repairs. While this video focuses on a straightforward process, stay tuned for more complex repairs in future content.

Tools of the Trade:

Now, let me walk you through the essential tools at my disposal—a preheater, two microscopes serving different purposes, and two soldering irons. I'll discuss my choice of flux, showcasing both a genuine Mechanic 559 and a Chinese alternative from Mtech. Flux is a critical element in reballing processes, and I'll emphasize its effectiveness in preventing burning out during repairs.

The Reballing Process:

Now, let's delve into the core of the video—the reballing process. Follow me as I meticulously detail each step, starting with the cleaning of the GDDR6 memory chip. I'll explain my choice of braids for different-sized chips and demonstrate how to cut a thin layer for optimal cleaning. I emphasize the importance of using lead-free solder for the reballing process.

Flux Application and Ball Placement:

Watch as I introduce the flux application using a syringe, explaining my preference for a specific flux's efficiency. I'll employ a 0.45mm leaded ball for the reballing, carefully placing them on the memory chip. Despite minor challenges with a few missing balls, my steady hand prevails as I successfully complete the placement.

Soldering with Hot Air Stations:

The video progresses to the soldering phase, where I utilize two hot air stations—an Atten 862D and a Quick 857DW. I'll activate the flux, adjust the air temperature, and expertly guide the hot air nozzle over the chip, allowing the solder balls to melt and settle into place. Witness the final touches as I ensure the balls adhere to the pads beneath.

Final Touches and Cleanup:

With the reballing complete, I'll inspect the chip, noting the cleanliness achieved with the chosen flux. While expressing the unnecessary but planned ultrasonic cleaning, I'll affirm the effectiveness of the process, showcasing the final, restored GDDR6 memory chip.

Conclusion:

In this comprehensive video, I've provided a beginner-friendly guide to reballing a GDDR6 memory chip. From setting up the workspace to choosing the right tools and demonstrating the reballing process, viewers gain valuable insights into a critical aspect of graphic card repairs. If you're looking to enhance your repair skills or delve into the world of GPU maintenance, this tutorial is a must-watch. Don't forget to like and subscribe for more insightful content from Graphic Card Repairs.